A (WPS) is the formal written document describing welding procedures, which provides direction to the welder or welding operators for making sound and quality production welds as per the code requirements . The purpose of the document is to guide welders to the accepted procedures so that repeatable and trusted welding techniques are used. A WPS is developed for each material alloy and for each welding type used. Specific codes and/or engineering societies are often the driving force behind the development of a company’s WPS. A WPS is supported by a Procedure Qualification Record (PQR or WPQR). A PQR is a record of a test weld performed and tested (more rigorously) to ensure that the procedure will produce a good weld obtained from the actual test samples.

Weld Procedure Qualifications

PWHT

Normalizing

Austenitizing

Tempering

Quenching

Hardness HV & HV

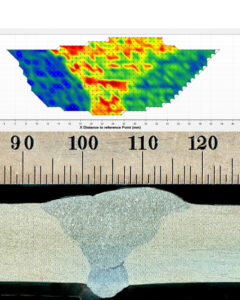

Automatic mapping

Module for 2D or 3D hardness mapping over areas or scanned contours. Creates a color map of the full surface, allowing to identify hardness variations and criticalities in the sample.

Ideal for extrapolation of mechanical properties of materials on the whole surface.

Weld measurement

Dedicated Weld Hardness

measurement module for defining patterns according to base material, HAZ and

Weld zone. Customizable pattern, it can be adapted to any weld geometries.

Allows accurate positioning of

the indents along the Fusion Line with specific distance from the surface

(according to international standards).

© 2022 Accu Test Labs LTD. All Right Reserved.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |